ERP system for supply chain management forms the backbone of modern logistics, orchestrating a complex dance of procurement, inventory, and delivery. This comprehensive guide delves into how these powerful systems transform operations, offering unprecedented visibility and control.

We will explore the fundamental role of an ERP system in managing the intricate network of supply chain operations, detailing its core functionalities and how it integrates disparate processes. Furthermore, we will examine the transformative benefits of implementing an ERP solution for optimizing efficiency, reducing costs, and enhancing customer satisfaction. The discussion will also cover critical features, architectural approaches, selection and implementation processes, and the integration of advanced technologies that further elevate supply chain capabilities.

The Fundamental Role of Enterprise Resource Planning in Supply Chain Management: Erp System For Supply Chain Management

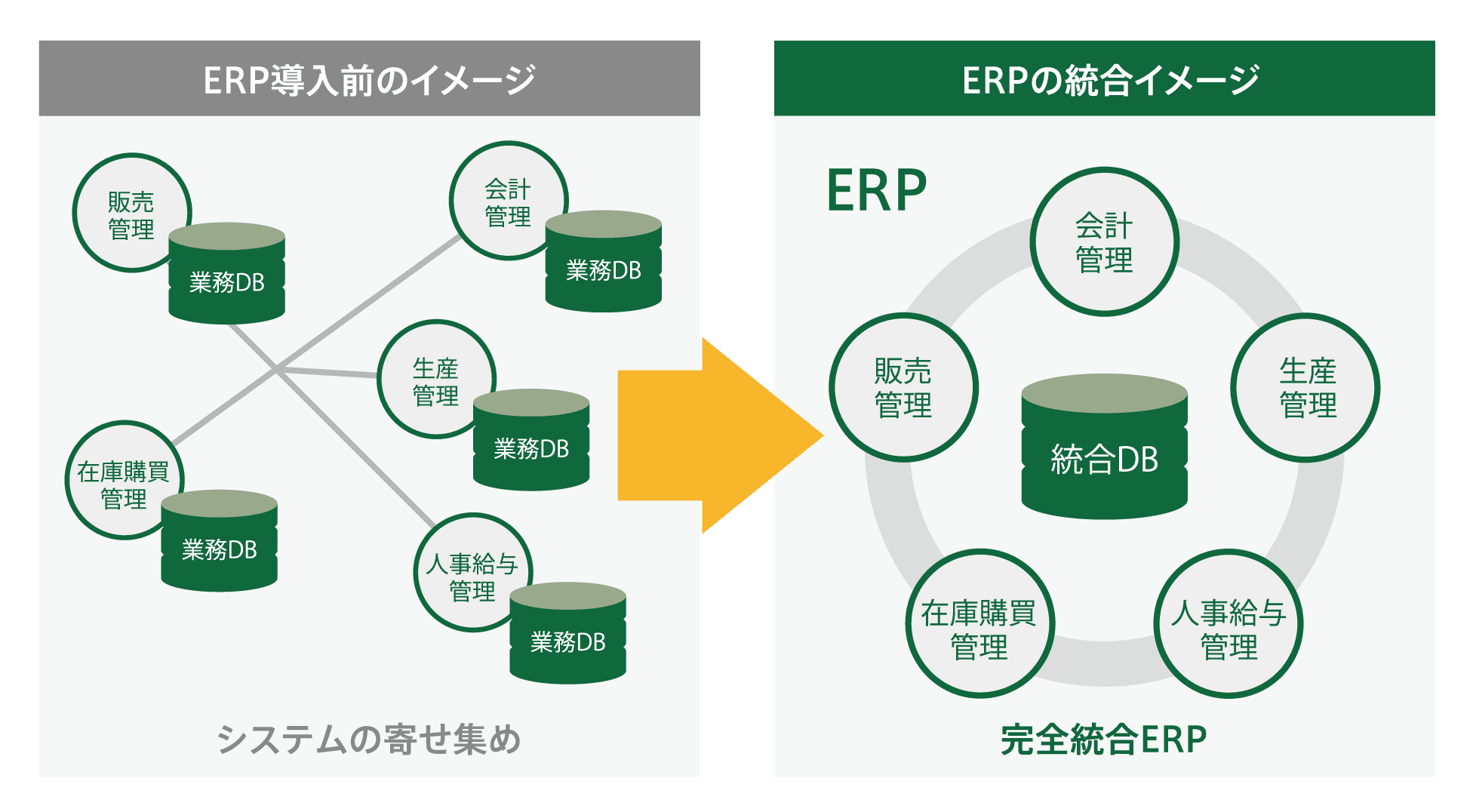

An Enterprise Resource Planning (ERP) system serves as the central nervous system for a modern supply chain, orchestrating a complex interplay of resources, information, and processes. Its fundamental role is to provide a unified, integrated platform that breaks down silos between different departments and functions, enabling seamless data flow and operational efficiency. In essence, an ERP system transforms a collection of independent activities into a cohesive, interconnected ecosystem, driving strategic decision-making and operational excellence across the entire supply chain lifecycle, from raw material sourcing to final product delivery.

It acts as the single source of truth, ensuring that all stakeholders have access to accurate, up-to-date information, thereby fostering collaboration, agility, and resilience in an increasingly dynamic global marketplace.The impact of an ERP system on supply chain visibility and control is profound and multifaceted. By consolidating data from various touchpoints, an ERP provides a comprehensive, real-time view of the entire supply chain.

This enhanced visibility allows businesses to proactively identify potential bottlenecks, disruptions, or inefficiencies before they escalate into significant problems. Core functionalities like demand forecasting, production planning, and inventory tracking are managed within the ERP, offering managers the ability to monitor stock levels, predict future demand based on historical data and market trends, and optimize production schedules accordingly. Procurement modules within the ERP track supplier performance, manage purchase orders, and ensure timely delivery of raw materials, while warehouse management functionalities offer precise control over inventory movement, storage, and picking processes.

Furthermore, transportation management features within an ERP can optimize routing, carrier selection, and freight costs, providing end-to-end visibility of goods in transit. This granular control over each stage of the supply chain empowers organizations to make informed decisions, reduce lead times, minimize stockouts, and ultimately improve customer satisfaction by ensuring products are available when and where they are needed. The system’s ability to generate detailed reports and analytics on key performance indicators (KPIs) further strengthens control, enabling continuous improvement and strategic adjustments to optimize supply chain performance.

Integration of Disparate Supply Chain Processes

An ERP system is designed to be the connective tissue that binds together previously fragmented supply chain processes, creating a unified and efficient operational framework. It achieves this by providing a common database and standardized workflows that allow information to flow freely between different functional areas. This integration is critical for overcoming the inherent complexities of modern supply chains, where various activities, from sourcing materials to delivering finished goods, often occur across different departments, geographical locations, and even external partner systems.The procurement process, for instance, is seamlessly linked to inventory management and finance.

When a purchase requisition is created in the ERP, it can automatically trigger a check of current inventory levels to determine if the item is truly needed. Upon approval, the purchase order is generated, which then informs the inventory system of incoming goods. Once the goods are received, the inventory levels are updated, and this information is simultaneously passed to the accounts payable module for payment processing.

This eliminates manual data entry, reduces the risk of errors, and ensures that inventory records are always accurate and up-to-date.Similarly, the integration between sales and production planning is crucial. Sales orders entered into the ERP system can directly influence production schedules. The system analyzes demand from sales orders, compares it against available inventory and production capacity, and then generates optimized production plans.

This ensures that manufacturing efforts are aligned with actual customer demand, preventing overproduction or underproduction. The ERP can also manage bills of materials (BOMs) and routings, providing detailed instructions for production and ensuring that the right components are available at the right time for manufacturing.Logistics and distribution are also deeply integrated. Once goods are manufactured or received, the ERP system can manage warehouse operations, including put-away, picking, packing, and shipping.

It can integrate with transportation management systems (TMS) to select optimal shipping routes and carriers, track shipments in real-transit, and manage freight costs. This end-to-end visibility ensures that products move efficiently through the supply chain and reach customers on time. The ability of an ERP to integrate these diverse processes into a single, coherent system is what allows businesses to achieve greater agility, reduce operational costs, and improve overall supply chain performance.

Enhancement of Decision-Making Through Real-Time Data Flow

The cornerstone of effective supply chain management in today’s fast-paced environment is the ability to make timely, data-driven decisions. An ERP system’s real-time data flow is instrumental in achieving this, providing decision-makers with immediate insights into critical aspects of the supply chain. This constant stream of accurate information empowers proactive problem-solving and strategic adjustments, moving away from reactive responses to issues.Consider the scenario of demand fluctuations.

Without real-time data, a company might rely on outdated sales reports or manual forecasts, leading to potential stockouts or excess inventory. However, with an ERP system, sales data from various channels—online orders, point-of-sale systems, and distributor reports—is updated instantaneously. This allows demand planners to see emerging trends, identify sudden spikes or dips in demand, and adjust production or procurement plans accordingly within minutes or hours, rather than days or weeks.

For example, if a popular product suddenly sees a surge in online orders, the ERP can alert the production and inventory teams, enabling them to expedite manufacturing or allocate existing stock to meet the unexpected demand, thereby preventing lost sales and maintaining customer satisfaction.Another critical area where real-time data flow enhances decision-making is inventory management. An ERP system provides an accurate, up-to-the-minute view of stock levels across all warehouses and distribution centers.

This allows inventory managers to identify slow-moving items, optimize reorder points, and prevent costly overstocking or stockouts. If a particular component used in manufacturing is running low in a specific facility, the ERP can immediately flag this, allowing procurement to initiate a rush order or reallocate inventory from another location. This real-time visibility prevents production delays and ensures that manufacturing processes are not interrupted due to material shortages.Logistics and transportation also benefit significantly.

Real-time tracking of shipments allows logistics managers to monitor the progress of goods, identify potential delays (due to weather, traffic, or carrier issues), and proactively communicate with customers or reroute shipments if necessary. For instance, if a critical shipment of raw materials is delayed en route, the ERP can alert the production manager, who can then adjust the production schedule to avoid downtime.

This proactive approach minimizes the impact of disruptions and ensures that goods reach their destination as efficiently as possible.Furthermore, real-time data on supplier performance, such as delivery times, quality adherence, and pricing, allows procurement managers to make informed decisions about supplier selection and negotiation. If a supplier consistently misses delivery deadlines, the ERP data will highlight this trend, enabling the procurement team to address the issue with the supplier or explore alternative sourcing options.

This continuous feedback loop, powered by real-time data, fosters a culture of continuous improvement and operational excellence across the entire supply chain.

Explore the transformative benefits of implementing an ERP solution for optimizing supply chain efficiency.

Implementing an Enterprise Resource Planning (ERP) system is a pivotal step for any organization aiming to revolutionize its supply chain operations. Beyond mere data management, an ERP acts as a central nervous system, connecting disparate functions and providing a unified view of the entire supply chain. This integration unlocks a cascade of benefits, fundamentally reshaping how businesses source, produce, and deliver goods.

The transformative power of ERP lies in its ability to drive efficiency, accuracy, and responsiveness across all stages, from raw material procurement to final customer delivery. By breaking down silos and fostering collaboration, an ERP system empowers businesses to navigate the complexities of modern supply chains with greater agility and foresight.The strategic integration of an ERP solution offers a multitude of advantages that directly impact a company’s bottom line and competitive standing.

It provides the foundational technology to achieve unprecedented levels of operational excellence. This comprehensive approach ensures that every decision is informed by real-time data, leading to proactive problem-solving and strategic optimization. The ripple effect of these improvements extends to enhanced customer loyalty, reduced waste, and ultimately, a stronger, more resilient business.

Reduction of Operational Costs Through Workflow Streamlining

One of the most significant advantages of adopting an ERP system in supply chain management is its profound impact on reducing operational costs. This is achieved primarily by streamlining workflows, eliminating redundancies, and automating manual processes that are often prone to errors and inefficiencies. Before ERP, many supply chain functions operated in isolation, leading to duplicated efforts, miscommunication, and delays.

For instance, procurement might not have real-time visibility into production schedules, resulting in rush orders and expedited shipping fees. Similarly, warehouse operations might not be synchronized with sales forecasts, leading to inefficient labor allocation and storage costs for excess inventory.An ERP system centralizes all these functions. Imagine a scenario where a sales order is entered into the ERP. This single entry can automatically trigger a series of coordinated actions: checking inventory availability, initiating a production order if necessary, updating raw material requirements, and scheduling logistics for delivery.

This eliminates the need for manual data re-entry across different departments, which not only saves time but also drastically reduces the likelihood of human error. The automation of tasks such as purchase order generation, invoice processing, and shipment tracking frees up valuable employee time, allowing them to focus on more strategic activities rather than administrative burdens. Furthermore, by providing a clear, end-to-end view of the supply chain, an ERP system helps identify bottlenecks and inefficiencies that were previously hidden.

For example, it can pinpoint areas where production lead times are consistently longer than expected or where transportation routes are suboptimal, enabling targeted improvements that lead to substantial cost savings. The ability to forecast demand more accurately, informed by historical data and real-time sales information, also plays a crucial role in cost reduction by minimizing waste and preventing costly overproduction or stockouts.

Ultimately, the unified data and automated processes facilitated by an ERP create a more agile and cost-effective supply chain.

Enhancement of Inventory Accuracy and Minimization of Stock Discrepancies

Inventory management is a critical, often challenging, aspect of supply chain operations. Inaccurate inventory data can lead to a host of problems, including lost sales due to stockouts, increased holding costs from overstocking, and inefficient use of warehouse space. An ERP system fundamentally transforms inventory accuracy by providing a single, authoritative source of truth for all inventory-related data. This means that every item, from raw materials to finished goods, is tracked in real-time across all locations.Before ERP, inventory counts might have been performed manually, with discrepancies often discovered only during physical audits or when a customer order could not be fulfilled.

This reactive approach leads to significant financial losses. With an ERP, inventory levels are updated instantaneously as goods are received, moved, or shipped. Barcode scanning and RFID technology, often integrated with the ERP, further enhance accuracy by automating data capture at every touchpoint. This real-time visibility allows for precise tracking of stock quantities, locations, and even batch or serial numbers, which is crucial for industries with strict traceability requirements.

The impact on stockouts is profound. When an ERP system accurately reflects inventory levels, sales and production teams can be confident in what is available. This prevents overselling and ensures that products are readily accessible when customer demand arises, leading to higher sales and improved customer satisfaction. Conversely, an ERP system also helps prevent overstock situations. By analyzing sales trends, lead times, and production capacities, the system can recommend optimal reorder points and safety stock levels.

This data-driven approach ensures that inventory is maintained at a level that meets demand without incurring excessive holding costs, such as warehousing, insurance, and potential obsolescence. For example, a clothing retailer using an ERP can track the sales velocity of specific sizes and colors, ensuring that popular items are replenished before they run out, while less popular items are not overproduced, thus minimizing markdowns and waste.

The integration of demand planning, procurement, and warehouse management within the ERP creates a holistic view that supports proactive inventory control, moving from a reactive “firefighting” mode to a strategic, data-informed approach.

Acceleration of Order Fulfillment and Improvement of Customer Satisfaction

The speed and accuracy with which orders are fulfilled are direct determinants of customer satisfaction and loyalty. An ERP system plays a pivotal role in accelerating this process, leading to a significantly enhanced customer experience. The interconnected nature of an ERP ensures that all departments involved in order processing – from sales and inventory management to production and logistics – operate with the same, up-to-date information.When a customer places an order, the ERP system immediately verifies product availability and flags any potential issues.

This real-time check prevents the acceptance of orders for out-of-stock items, which would inevitably lead to delays and customer disappointment. Once an order is confirmed, the ERP can automatically generate pick lists for the warehouse, optimize picking routes to minimize travel time, and initiate the packing and shipping process. This automation and optimization drastically reduce the time it takes to get an order from the system to the customer’s doorstep.

Furthermore, an ERP system facilitates better communication and coordination between departments. For instance, if production needs to be expedited to meet a critical customer order, the ERP can immediately notify the production planning team and adjust schedules accordingly. Similarly, logistics can be alerted to prepare for an outgoing shipment, ensuring that transportation is booked and ready. This seamless flow of information minimizes handoffs and delays that are common in non-integrated systems.

The ability of an ERP to provide real-time order tracking information to both internal teams and customers is another key factor in improving satisfaction. Customers can be kept informed about the status of their orders, from confirmation to shipment and delivery, fostering transparency and reducing the need for them to contact customer service for updates. This proactive communication builds trust and enhances the overall customer experience.

By enabling faster, more accurate, and more transparent order fulfillment, an ERP system directly contributes to higher customer retention rates and positive word-of-mouth, which are invaluable assets for any business.

Scenario: The “Before and After” Impact of ERP Implementation on a Hypothetical Supply Chain

Consider “Acme Gadgets,” a mid-sized electronics manufacturer that has historically struggled with supply chain inefficiencies. Before implementing an ERP system, Acme Gadgets operated with a fragmented approach. Their sales team relied on spreadsheets to track orders, often unaware of actual inventory levels in the warehouse. The procurement department worked with manual purchase requisitions, frequently placing rush orders due to unforeseen shortages, incurring hefty expedited shipping fees.

Production schedules were often dictated by gut feeling rather than precise demand forecasts, leading to either overproduction of slow-moving items or critical stockouts of popular gadgets. Warehouse operations were managed with a separate inventory system, often out of sync with sales orders, resulting in picking errors and delayed shipments. Customer complaints about late deliveries and incorrect orders were common.The implementation of a comprehensive ERP system at Acme Gadgets brought about a dramatic transformation.

The sales team now has real-time visibility into finished goods inventory directly within the ERP. When a customer places an order, the system instantly confirms availability, and if stock is low, it automatically flags the need for replenishment. The procurement department’s workflow is now integrated with production planning and sales forecasts. The ERP system automatically generates purchase requisitions based on optimal reorder points and anticipated demand, significantly reducing the need for costly rush orders.

Production planning is now data-driven; the ERP analyzes sales trends, lead times, and raw material availability to create optimized production schedules, minimizing waste and ensuring that popular items are always in stock.The warehouse operations have been revolutionized. With integrated barcode scanning and real-time inventory updates, picking errors have plummeted. The ERP system guides pickers with optimized routes, speeding up order preparation.

Shipment tracking is now automated, providing instant updates to customers via email or a customer portal. The result for Acme Gadgets has been a significant reduction in operational costs, with a 15% decrease in expedited shipping fees and a 20% reduction in inventory holding costs within the first year. Inventory accuracy has improved from an estimated 80% to over 98%, leading to a 30% decrease in stockouts and a 25% reduction in overstock situations.

Most importantly, customer satisfaction has soared, with a 40% reduction in delivery-related complaints and a noticeable increase in repeat business, showcasing the tangible benefits of a unified and efficient supply chain powered by ERP.

Identifying Critical ERP Features for Modern Supply Chain Management

Modern supply chains are intricate ecosystems, characterized by global reach, dynamic demand, and constant flux. To navigate this complexity effectively, an Enterprise Resource Planning (ERP) system must be equipped with a specific set of critical features. These functionalities are not merely optional add-ons; they are fundamental to achieving operational excellence, fostering resilience, and driving competitive advantage. An effective ERP acts as the central nervous system of the supply chain, integrating disparate processes, providing real-time visibility, and enabling proactive decision-making.

Without these core capabilities, businesses risk falling behind, struggling with inefficiencies, stockouts, excess inventory, and an inability to respond swiftly to market changes. The following sections delve into the essential modules and functionalities that define a powerful ERP for supply chain management.

Comparing and Contrasting ERP Architectural Approaches for Supply Chain Management

The selection of an appropriate architectural approach for an Enterprise Resource Planning (ERP) system is a pivotal decision that profoundly impacts its effectiveness in managing complex supply chain operations. Different architectures offer distinct trade-offs in terms of cost, flexibility, scalability, security, and implementation complexity. Understanding these differences is crucial for organizations aiming to optimize their supply chains and achieve strategic business objectives.

This section delves into the prominent architectural models, analyzing their strengths and weaknesses in the context of modern supply chain management.

On-Premises ERP Solutions for Supply Chain Operations

On-premises ERP solutions represent the traditional deployment model where the software and all associated hardware are installed and managed within the organization’s own data centers. For supply chain operations, this approach offers a high degree of control and customization. Organizations can tailor the system precisely to their unique workflows, integrating it seamlessly with existing legacy systems and ensuring that data resides entirely within their own secure network.

This level of control can be particularly advantageous for companies dealing with highly sensitive data or operating in industries with stringent regulatory compliance requirements. The ability to deeply customize the system allows for the fine-tuning of every aspect of the supply chain, from procurement and inventory management to logistics and distribution, potentially leading to highly optimized processes. Furthermore, the upfront investment in hardware and software, while substantial, can be viewed as a capital expenditure, which may align better with certain financial strategies.

The responsibility for maintenance, upgrades, and security rests entirely with the organization, providing a clear line of accountability.However, this model comes with significant disadvantages. The initial capital outlay for hardware, software licenses, and implementation services can be exceedingly high, posing a barrier to entry for smaller businesses. The ongoing costs associated with maintaining the infrastructure, including IT staff, power, cooling, and regular hardware refreshes, can also be substantial.

Customization, while a benefit, can also lead to vendor lock-in and make future upgrades more complex and costly. Scalability can be a challenge; expanding capacity often requires significant hardware investments and lengthy implementation times. Security, while under the organization’s direct control, also means the organization bears the full responsibility for protecting its data against evolving cyber threats. Downtime due to hardware failures or maintenance can disrupt critical supply chain operations, and the IT department must possess the expertise to manage and troubleshoot the entire system.

The time to implement an on-premises ERP can also be considerably longer compared to cloud-based alternatives, delaying the realization of potential benefits.

Cloud-Based ERP Systems for Managing Global Supply Chains

Cloud-based ERP systems, also known as Software as a Service (SaaS) ERP, are hosted on the vendor’s servers and accessed over the internet. This model has become increasingly popular for managing global supply chains due to its inherent flexibility and scalability. For organizations with geographically dispersed operations, a cloud ERP offers a unified platform accessible from anywhere with an internet connection, facilitating real-time collaboration and data sharing across different regions and time zones.

This eliminates the need for extensive on-site IT infrastructure at each location, significantly reducing capital expenditure and operational overhead. Vendors typically manage the infrastructure, maintenance, and security, freeing up the organization’s IT resources to focus on more strategic initiatives. Updates and new features are often rolled out automatically by the vendor, ensuring that the system remains current without significant internal effort.

The subscription-based pricing model provides predictable operational expenses, making budgeting easier. Scalability is a major advantage; organizations can easily scale their usage up or down based on demand, adding or removing users and functionalities as needed. This agility is invaluable in dynamic global supply chains that experience seasonal fluctuations or rapid growth.Despite these benefits, cloud-based ERP systems present their own set of challenges.

Data security and privacy are paramount concerns. While reputable cloud vendors invest heavily in security measures, organizations must still conduct thorough due diligence to ensure the vendor’s compliance with relevant data protection regulations and industry standards. Reliance on internet connectivity means that disruptions can lead to system unavailability, impacting supply chain operations. Customization options in cloud ERPs are often more limited compared to on-premises solutions, as the vendor maintains a standardized platform for all clients.

While many cloud ERPs offer extensive configuration options, deep, code-level customization may not be feasible, which could be a drawback for organizations with highly specialized requirements. Integration with legacy on-premises systems can also be more complex, requiring robust APIs and middleware. Vendor lock-in can also be a concern; migrating data and processes from one cloud provider to another can be a significant undertaking.

Performance can sometimes be an issue, depending on internet bandwidth and latency, particularly for users in remote locations.

Hybrid ERP Models and Their Suitability for Diverse Supply Chain Needs

Hybrid ERP models represent a blended approach, combining elements of both on-premises and cloud-based deployments to leverage the advantages of each. This model is particularly well-suited for organizations with diverse and evolving supply chain needs, allowing them to strategically place different components of their ERP system in the most appropriate environment. For instance, a company might choose to host its core financial and HR modules on-premises for maximum control and security, while utilizing a cloud-based solution for customer relationship management (CRM) or warehouse management systems (WMS) that require broad accessibility and rapid scalability.

This approach allows organizations to retain control over their most critical or sensitive data and processes while benefiting from the agility and cost-effectiveness of cloud solutions for other functions. It offers a phased migration path, enabling organizations to move to the cloud incrementally, reducing the risk and disruption associated with a complete overhaul. Hybrid models can also facilitate integration between existing on-premises systems and new cloud applications, providing a bridge for digital transformation.The suitability of hybrid ERP for diverse supply chain needs stems from its inherent flexibility.

Organizations can tailor their deployment to match the specific characteristics of different supply chain segments. For example, a manufacturing division with highly integrated, proprietary processes might benefit from an on-premises ERP, while a global sales and distribution network could thrive on a cloud-based solution for real-time visibility and collaboration. This model can also accommodate organizations that have acquired other companies with different ERP systems, allowing them to integrate these disparate systems into a cohesive hybrid architecture.

It provides a pragmatic solution for companies that are not yet ready for a full cloud migration but want to embrace the benefits of cloud technology for specific functionalities. The ability to optimize costs by placing workloads in the most economical environment is another significant advantage.However, managing a hybrid ERP environment can introduce complexity. Integrating on-premises and cloud components requires robust IT expertise and careful planning to ensure seamless data flow and interoperability.

Organizations need to manage multiple vendors, each with their own service level agreements (SLAs) and support structures, which can complicate IT management and troubleshooting. Security becomes a shared responsibility, requiring a comprehensive security strategy that spans both on-premises infrastructure and cloud services. The potential for data silos between different components of the system needs to be carefully managed to maintain a unified view of the supply chain.

While hybrid models offer flexibility, they can also lead to higher overall IT management costs if not planned and executed efficiently.

Conceptual Framework for Evaluating ERP Deployment Strategies Based on Specific Supply Chain Characteristics

Evaluating ERP deployment strategies requires a systematic approach that aligns the chosen architecture with the unique characteristics and strategic objectives of an organization’s supply chain. A conceptual framework can guide this decision-making process, ensuring that the chosen ERP solution enhances rather than hinders supply chain performance. This framework should consider several key dimensions of the supply chain, alongside organizational factors.One crucial dimension is the Geographic Distribution of the Supply Chain.

For highly localized supply chains with minimal international operations, an on-premises solution might offer sufficient control and customization without the need for extensive global accessibility. Conversely, global supply chains with numerous international partners, manufacturing sites, and distribution centers will benefit significantly from the inherent accessibility and real-time collaboration capabilities of cloud-based ERPs. Hybrid models can serve as an excellent compromise for organizations with a mix of centralized and distributed operations.Another critical factor is the Complexity and Uniqueness of Supply Chain Processes.

Organizations with highly standardized and common supply chain processes might find off-the-shelf cloud ERP solutions to be a cost-effective and efficient choice. However, businesses with highly specialized, proprietary, or complex workflows that require deep customization may lean towards on-premises solutions or a hybrid approach that allows for bespoke on-premises components. The ability to integrate with specialized legacy systems also plays a role; if these systems are deeply embedded and critical, on-premises or hybrid solutions might be more practical.The Regulatory and Compliance Landscape is also a significant determinant.

Industries with stringent data privacy regulations (e.g., healthcare, finance) or those handling sensitive intellectual property might prefer the enhanced control and data residency options offered by on-premises or private cloud deployments. Public cloud solutions require careful vetting of the vendor’s compliance certifications and security protocols. IT Infrastructure and Resource Availability are practical considerations. Organizations with a robust and skilled internal IT department might be well-equipped to manage the complexities of an on-premises deployment.

Conversely, companies with limited IT resources or those seeking to offload infrastructure management responsibilities will find cloud-based solutions more appealing.Finally, Budgetary Constraints and Financial Strategy are paramount. On-premises ERPs represent a significant capital expenditure, while cloud ERPs typically involve operational expenditure through subscription fees. A hybrid model can offer a balanced approach, allowing for strategic allocation of capital and operational budgets. The total cost of ownership (TCO), including implementation, maintenance, upgrades, and ongoing support, should be carefully analyzed for each architectural approach.The framework can be visualized as a matrix where the supply chain characteristics are mapped against the architectural options, with decision-making criteria guiding the selection.

For instance, a supply chain characterized by high geographic distribution, moderate process complexity, and a need for rapid scalability would strongly favor a public cloud ERP. A supply chain with low geographic distribution, high process complexity, and strict data sovereignty requirements might point towards an on-premises solution. A supply chain exhibiting moderate distribution, high complexity in certain areas, and a need for phased modernization would likely benefit from a hybrid approach.

This structured evaluation ensures that the ERP architecture chosen directly supports and enhances the organization’s specific supply chain objectives and operational realities.

Illustrate the process of selecting and implementing an ERP system tailored to specific supply chain requirements.

Selecting and implementing an Enterprise Resource Planning (ERP) system for supply chain management is a strategic undertaking that demands careful planning and execution. It’s not merely a technological upgrade but a fundamental shift in how an organization manages its entire value chain, from raw material procurement to final product delivery. A well-chosen and effectively implemented ERP system can unlock significant efficiencies, enhance visibility, and provide a competitive edge.

The process involves a deep dive into current operational pain points, a clear vision for future state, and a rigorous evaluation of available solutions and vendor capabilities. This detailed exploration will guide you through the essential phases of this critical journey.The successful integration of an ERP system into a supply chain environment is a multifaceted endeavor. It begins with a thorough understanding of the organization’s unique needs and culminates in a fully functional, adopted system.

This requires a systematic approach, moving from initial strategic alignment to the granular details of data management and user engagement. The following sections will break down these crucial stages, offering practical insights and best practices to navigate this complex process effectively.

Defining Business Needs and Evaluating ERP Vendors for Supply Chain Applications, Erp system for supply chain management

The foundation of any successful ERP implementation lies in a comprehensive understanding of the business’s specific needs within the supply chain. This involves a meticulous analysis of current processes, identifying bottlenecks, inefficiencies, and areas ripe for improvement. Stakeholder interviews across all relevant departments – procurement, logistics, warehousing, manufacturing, sales, and finance – are paramount. This collaborative approach ensures that all critical requirements are captured, from real-time inventory tracking and demand forecasting accuracy to supplier performance management and transportation optimization.

Documenting these needs in a clear, prioritized list of functional and non-functional requirements serves as the blueprint for vendor evaluation. Key areas to scrutinize include the system’s ability to handle complex bill of materials, manage multiple warehouses and distribution centers, support various shipping modes, and integrate with external partners.Vendor evaluation should be a structured and objective process. Start by shortlisting vendors with a proven track record in supply chain ERP solutions.

Request detailed demonstrations that are tailored to your specific use cases, rather than generic product tours. Pay close attention to the vendor’s understanding of your industry and their proposed solution’s ability to address your identified pain points. Key evaluation criteria should include:

- Functionality Fit: Does the ERP system offer modules and features that directly address your supply chain requirements? This includes capabilities like advanced planning and scheduling (APS), warehouse management systems (WMS), transportation management systems (TMS), and demand planning.

- Scalability and Flexibility: Can the system grow with your business and adapt to changing market conditions and future expansion plans? Consider its ability to handle increasing transaction volumes and new geographical markets.

- Technology and Architecture: Assess the underlying technology stack, its robustness, security features, and compatibility with existing IT infrastructure. Cloud-based versus on-premise deployment options should be carefully weighed.

- Vendor Reputation and Support: Research the vendor’s financial stability, customer satisfaction ratings, and the quality of their post-implementation support and training services.

- Total Cost of Ownership (TCO): Beyond initial licensing fees, consider implementation costs, customization expenses, ongoing maintenance, support, and training.

Requesting references from similar companies within your industry is a crucial step. Engage in thorough contract negotiations, ensuring clarity on service level agreements (SLAs), intellectual property rights, and data ownership. A robust Request for Proposal (RFP) process, followed by detailed demonstrations and reference checks, will significantly de-risk the vendor selection process and set the stage for a successful implementation.

Practical Advice on Best Practices for Data Migration and System Integration during ERP Implementation

Data migration and system integration are often cited as the most challenging aspects of an ERP implementation. Inaccurate or incomplete data can cripple a new system, rendering its powerful functionalities useless. Similarly, poor integration can lead to data silos, manual workarounds, and a failure to achieve the desired end-to-end visibility. Therefore, a strategic and meticulous approach to these phases is non-negotiable.The process of data migration should commence early in the project lifecycle.

Begin by identifying all critical data sources that need to be migrated from legacy systems to the new ERP. This includes master data (e.g., customer, supplier, product information), transactional data (e.g., open orders, outstanding invoices), and historical data. A comprehensive data cleansing strategy is essential. This involves identifying and rectifying inaccuracies, duplicates, and inconsistencies in the existing data. It’s often beneficial to involve business users in this process, as they possess the most intimate knowledge of the data’s meaning and context.

Develop a detailed data mapping plan, clearly defining how data fields in the old system correspond to fields in the new ERP.

“Garbage in, garbage out” is a timeless adage that holds particularly true for ERP implementations. Ensuring data accuracy and integrity from the outset is paramount for realizing the system’s full potential.

Before the actual migration, conduct multiple test migrations in a non-production environment. This allows for the identification and resolution of any data transformation issues or errors. A phased approach to data migration, starting with less critical data and progressively moving to more complex datasets, can also mitigate risks. Establish clear data validation procedures to confirm the accuracy and completeness of migrated data before the go-live.System integration involves connecting the new ERP system with other existing software applications that are critical to supply chain operations.

This could include Customer Relationship Management (CRM) systems, Warehouse Management Systems (WMS) if not fully integrated within the ERP, Transportation Management Systems (TMS), and e-commerce platforms. APIs (Application Programming Interfaces) are the modern standard for facilitating seamless integration, allowing different systems to communicate and exchange data in real-time.Best practices for integration include:

- Define Integration Scope Clearly: Identify which systems need to integrate and the specific data flows required for each integration point.

- Choose the Right Integration Strategy: Decide between point-to-point integrations, middleware solutions, or an Enterprise Service Bus (ESB) based on complexity and future scalability needs.

- Standardize Data Formats: Ensure that data exchanged between systems uses consistent formats to avoid translation errors.

- Thorough Testing: Rigorously test all integrations in a staging environment to ensure data flows correctly and that system performance is not negatively impacted.

- Documentation: Maintain comprehensive documentation for all integration points, including data mappings, protocols, and error handling procedures.

Engage experienced integration specialists, whether internal or external, to manage this complex task. Proactive planning, meticulous execution, and continuous monitoring are key to achieving robust and reliable system integrations.

The Critical Role of User Training and Change Management in Ensuring Successful ERP Adoption for Supply Chain Teams

Even the most sophisticated ERP system will fail to deliver its promised benefits if users do not adopt it effectively. User training and robust change management strategies are not mere add-ons; they are foundational pillars for successful ERP implementation, particularly within dynamic supply chain environments. Supply chain teams often operate under pressure, with tight deadlines and a constant need for accurate, real-time information.

Resistance to change, lack of understanding, or inadequate training can lead to frustration, errors, and ultimately, a return to old, inefficient practices.Effective user training should be tailored to different user roles and responsibilities within the supply chain. A warehouse operative will require different training than a supply chain planner or a procurement manager. Training should not be a one-off event but an ongoing process.

Initial training should cover core functionalities, while subsequent sessions can delve into advanced features and best practices. Hands-on training in a simulated environment that mirrors real-world scenarios is highly effective. This allows users to practice navigating the system, performing essential tasks, and troubleshooting common issues without the risk of impacting live operations.

“People are the key to unlocking technology’s potential. Without their buy-in and proficiency, even the most advanced ERP system remains an underutilized asset.”

Change management, on the other hand, focuses on preparing the organization for the new system and addressing the human element of the transition. This begins with clear and consistent communication from leadership, explaining the rationale behind the ERP implementation, its benefits, and the expected impact on employees. Early and frequent engagement with stakeholders helps to build trust and mitigate anxieties.Key change management activities include:

- Stakeholder Analysis: Identify all groups affected by the ERP implementation and understand their potential concerns and resistance points.

- Communication Plan: Develop a comprehensive communication strategy that Artikels key messages, communication channels, and frequency.

- Impact Assessment: Analyze how the new ERP system will alter existing roles, responsibilities, and workflows.

- Resistance Management: Proactively identify and address potential sources of resistance through open dialogue, feedback mechanisms, and tailored support.

- Champion Network: Establish a network of internal champions – influential individuals who can advocate for the new system and support their peers.

- Post-Implementation Support: Ensure that ongoing support mechanisms are in place to address user queries and reinforce learning after the go-live.

By investing in comprehensive training and a well-executed change management program, organizations can foster a culture of adoption, empower their supply chain teams with the skills and confidence to leverage the ERP system, and ultimately achieve the desired operational improvements and strategic advantages.

A Phased Implementation Plan for an ERP System in a Complex, Multi-National Supply Chain Environment

Implementing an ERP system in a complex, multi-national supply chain environment is akin to orchestrating a symphony. It requires careful coordination across diverse geographies, business units, and regulatory landscapes. A “big bang” approach, where all modules are rolled out simultaneously across all locations, is often too risky and disruptive in such settings. Therefore, a phased implementation plan is generally the most prudent and effective strategy.

This approach allows for learning and refinement at each stage, minimizing disruption and maximizing the chances of success.The phased plan should be built around logical groupings of functionality, geographical regions, or business units. A common approach is to start with a core set of modules that provide the most immediate value and are foundational for subsequent phases.Here’s a potential phased implementation plan:

Phase 1: Foundation and Core Operations (e.g., 6-12 months)

- Focus: Establishing core financial and procurement processes, master data management, and basic inventory control across key regions or a pilot country.

- Modules: General Ledger, Accounts Payable/Receivable, Procurement, Inventory Management (basic).

- Activities: Data cleansing and migration for core master data, initial system configuration, user training for core finance and procurement teams, pilot testing in a designated region.

- Objective: Stabilize core financial and procurement operations, gain initial user adoption, and validate the ERP’s fundamental capabilities.

Phase 2: Expanding Operational Visibility and Control (e.g., 9-15 months)

- Focus: Integrating manufacturing, advanced inventory management, and initial logistics functionalities across a broader set of locations.

- Modules: Manufacturing Execution System (MES) integration, Warehouse Management System (WMS), Sales Order Management, basic Transportation Management System (TMS) features.

- Activities: Migrating relevant manufacturing and inventory data, configuring WMS and TMS modules, integrating with existing production systems, training expanded user groups.

- Objective: Enhance operational efficiency, improve inventory accuracy, and gain better visibility into production and outbound logistics.

Phase 3: Advanced Supply Chain Planning and Optimization (e.g., 12-18 months)

Phase 4: Integration with External Partners and Analytics (e.g., 6-12 months)

- Focus: Integrating with key external partners (suppliers, customers, logistics providers) and leveraging the ERP’s analytical capabilities for strategic decision-making.

- Modules: Electronic Data Interchange (EDI) capabilities, Business Intelligence (BI) and Analytics modules, Customer Portal integration.

- Activities: Setting up EDI connections, developing custom reports and dashboards, training analytics teams and relevant external stakeholders.

- Objective: Streamline B2B transactions, enable data-driven strategic planning, and foster greater collaboration across the extended supply chain.

Each phase should include rigorous testing, user acceptance testing (UAT), and a post-implementation review to capture lessons learned before proceeding to the next. This iterative approach allows for flexibility, adaptation to unforeseen challenges, and a more manageable transition for a complex, multi-national supply chain. The key is to ensure that each phase delivers tangible value and builds momentum for the overall ERP success.

Examine the role of advanced technologies integrated with ERP systems to further enhance supply chain capabilities.

The integration of advanced technologies with Enterprise Resource Planning (ERP) systems is no longer a futuristic concept but a present-day imperative for organizations aiming to achieve peak supply chain performance. These technologies, when seamlessly woven into the fabric of an ERP, unlock unprecedented levels of efficiency, agility, and intelligence. They move beyond traditional data management to provide real-time insights, predictive capabilities, and automated execution, fundamentally transforming how supply chains operate.

This synergy allows businesses to navigate complex global networks, respond swiftly to market dynamics, and proactively mitigate risks, ultimately leading to a more robust and competitive supply chain.The power of an ERP system is amplified exponentially when augmented by cutting-edge technologies. These integrations enable a shift from reactive problem-solving to proactive optimization, allowing for more informed decision-making and a greater capacity to anticipate and adapt to challenges.

By embedding technologies like the Internet of Things (IoT), Artificial Intelligence (AI), Machine Learning (ML), blockchain, and Robotic Process Automation (RPA) within the ERP framework, companies can achieve a level of granular control and predictive foresight previously unimaginable. This holistic approach ensures that every facet of the supply chain, from raw material sourcing to final product delivery, is optimized for speed, cost-effectiveness, and customer satisfaction.

Internet of Things (IoT) Integration for Granular Supply Chain Visibility

The Internet of Things (IoT) fundamentally reshapes supply chain visibility by connecting physical assets to the digital realm, generating a continuous stream of real-time data that feeds directly into the ERP system. This constant flow of information provides an unprecedented level of detail about the location, condition, and status of goods and assets throughout the entire supply chain lifecycle. Imagine a fleet of delivery trucks equipped with GPS trackers and temperature sensors.

As these trucks move, their precise location is updated in the ERP system in real-time, allowing logistics managers to monitor delivery progress, estimate arrival times with high accuracy, and reroute vehicles dynamically in response to traffic or other disruptions.Furthermore, IoT sensors can monitor environmental conditions such as temperature, humidity, and shock during transit. For perishable goods like pharmaceuticals or fresh produce, this is critical.

The ERP system can then receive alerts if these parameters deviate from acceptable ranges, triggering immediate corrective actions, such as notifying the driver or initiating a quality control check upon arrival. This granular data also extends to warehouse operations. Smart shelves equipped with weight sensors can automatically track inventory levels, triggering reorder alerts when stock falls below a predefined threshold, thereby preventing stockouts and optimizing inventory management.

Similarly, RFID tags on individual products or pallets provide precise tracking from the point of manufacture through to the point of sale. The ERP system, by aggregating this IoT data, creates a digital twin of the physical supply chain, offering a comprehensive and up-to-the-minute view that empowers better decision-making, reduces waste, and enhances overall operational efficiency. This level of detail allows for proactive identification of bottlenecks, improved asset utilization, and a more responsive and resilient supply chain.

Artificial Intelligence (AI) and Machine Learning (ML) for Predictive Analytics in Supply Chain Optimization

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing supply chain optimization by transforming raw data into actionable predictive insights within ERP systems. These technologies enable the forecasting of future events with a significantly higher degree of accuracy than traditional methods, allowing businesses to move from reactive to proactive management. ML algorithms can analyze vast historical datasets, including sales patterns, weather forecasts, economic indicators, and even social media trends, to predict demand with remarkable precision.

For instance, an ERP system powered by ML can forecast the demand for a specific product in a particular region weeks or months in advance, taking into account seasonal variations, promotional activities, and competitor actions. This predictive capability allows for optimized production scheduling, better inventory planning, and reduced instances of overstocking or stockouts, thereby minimizing costs and maximizing sales opportunities.Beyond demand forecasting, AI and ML can predict potential disruptions within the supply chain.

By analyzing patterns in supplier performance, geopolitical events, and logistical data, these technologies can identify potential risks such as supplier delays, transportation issues, or natural disasters. The ERP system can then alert relevant stakeholders, suggesting alternative suppliers or transportation routes, thereby mitigating the impact of these disruptions. For example, an ML model might detect an increasing probability of a port strike based on news feeds and labor union activity, prompting the ERP to suggest rerouting shipments through alternative ports or using different modes of transport.

Furthermore, AI can optimize inventory levels by dynamically adjusting reorder points and safety stock based on predicted demand fluctuations and lead times. This leads to significant cost savings by reducing carrying costs for excess inventory while ensuring that sufficient stock is available to meet customer needs. The integration of AI and ML into ERP systems essentially creates an intelligent supply chain that learns, adapts, and anticipates, driving continuous improvement and a competitive edge.

Blockchain Technology for Enhanced Supply Chain Transparency and Traceability

Blockchain technology, when coupled with an ERP system, offers a robust and immutable ledger that significantly enhances supply chain transparency and traceability. At its core, blockchain is a decentralized, distributed ledger that records transactions across many computers in such a way that any attempt to alter the record is immediately evident. In the context of a supply chain, this means that every movement, transaction, and change of ownership of a product can be recorded on the blockchain, creating a single, verifiable source of truth accessible to all authorized participants.

For example, when a raw material is sourced from a supplier, its origin, quality certifications, and transfer of ownership can be recorded as a block on the chain. As this material moves through various stages of production, assembly, and distribution, each step is added as a new block, linked chronologically and cryptographically to the previous one.This immutable record provides unparalleled traceability.

If a product recall is necessary, or if there’s a question about the authenticity or origin of a component, the ERP system can query the blockchain to pinpoint the exact source and history of the item. This is particularly crucial in industries like pharmaceuticals, food and beverage, and luxury goods, where counterfeiting and product integrity are paramount concerns. Consumers, regulators, and businesses can all access this transparent record, verifying claims about ethical sourcing, organic certification, or fair trade practices.

For instance, a consumer could scan a QR code on a product, and the ERP system, interacting with the blockchain, would display the entire journey of that product from farm to shelf, including all relevant certifications and quality checks. Furthermore, blockchain can streamline reconciliation processes. Instead of manual verification of invoices and shipping documents, smart contracts on the blockchain can automatically trigger payments or confirm receipt of goods once predefined conditions are met, reducing disputes and accelerating financial settlements.

This heightened transparency and traceability foster trust among supply chain partners and build stronger, more reliable relationships.

Robotic Process Automation (RPA) for Automating Routine Tasks in ERP-Managed Supply Chains

Robotic Process Automation (RPA) plays a crucial role in streamlining ERP-managed supply chains by automating repetitive, rule-based tasks that traditionally consume significant human resources. RPA bots are software programs that mimic human actions to interact with digital systems, including ERP interfaces, to perform tasks such as data entry, form filling, report generation, and basic data validation. Within an ERP system, these bots can automate a multitude of mundane processes, freeing up human employees to focus on more strategic and value-added activities.

For example, when a new purchase order is received, an RPA bot can be programmed to automatically extract relevant information from the order, such as item numbers, quantities, and pricing, and input this data into the ERP system’s procurement module. This eliminates the risk of manual data entry errors and speeds up the order processing cycle considerably.Another significant application of RPA is in invoice processing.

Bots can be configured to retrieve invoices from email inboxes or other digital sources, extract key data points like vendor name, invoice number, and amount, and then match this information against corresponding purchase orders and goods receipts already stored in the ERP. If all matches are successful, the bot can automatically approve the invoice for payment or flag any discrepancies for human review.

This dramatically reduces the time and effort required for accounts payable departments and improves payment accuracy. RPA can also automate the generation of standard reports. For instance, weekly inventory reports, daily sales summaries, or shipping status updates can be automatically compiled by bots from ERP data and distributed to relevant stakeholders via email or other communication channels. This ensures timely dissemination of information and reduces the manual effort involved in report creation.

By taking over these routine tasks, RPA enhances the efficiency of the ERP system, reduces operational costs, minimizes errors, and allows supply chain professionals to dedicate their expertise to more complex problem-solving, strategic planning, and customer engagement.

Summary

In essence, an ERP system for supply chain management is no longer a luxury but a necessity for businesses striving for agility and competitiveness. By centralizing data, automating processes, and providing real-time insights, these systems empower organizations to navigate the complexities of global supply chains with confidence. Embracing the right ERP solution, coupled with strategic implementation and integration of emerging technologies, paves the way for enhanced operational efficiency, reduced costs, and ultimately, superior customer experiences.

Popular Questions

What is the primary goal of an ERP system in supply chain management?

The primary goal is to integrate and streamline all aspects of the supply chain, from procurement to delivery, to improve efficiency, visibility, and decision-making.

How does an ERP system improve inventory accuracy?

By providing real-time tracking of inventory levels, movements, and sales, ERP systems minimize manual errors, reduce stockouts, and prevent overstocking.

Can an ERP system help with demand forecasting?

Yes, advanced ERP systems include modules for demand forecasting that analyze historical data, market trends, and other factors to predict future demand more accurately.

What is the difference between on-premises and cloud-based ERP for supply chains?

On-premises ERP is installed and managed on a company’s own servers, offering greater control but higher upfront costs. Cloud-based ERP is hosted by a vendor, offering flexibility, scalability, and often lower initial investment, with subscription-based pricing.

How important is user training for ERP implementation in supply chains?

User training is critical. Without proper training, supply chain teams may not be able to effectively utilize the ERP system’s features, leading to adoption issues and suboptimal results.