Enterprise resource planning sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with casual formal language style and brimming with originality from the outset.

This comprehensive exploration delves into the foundational principles and evolution of integrated business management systems, dissecting the multifaceted modules that constitute modern solutions. We will navigate the strategic advantages and tangible benefits of implementing such platforms, charting the intricate journey of selection and deployment. Furthermore, we will explore the dynamic interplay between enterprise resource planning systems and emerging technological advancements, while identifying potential obstacles and mitigation strategies encountered during their operationalization.

This detailed examination aims to provide a thorough understanding of ERP’s impact on businesses of all sizes.

The Fundamental Evolution of Integrated Business Management Systems and Their Foundational Principles

In the early days of business computing, the landscape of software was largely fragmented. Each department within an organization often operated with its own bespoke system, designed to address specific, narrow functions. This siloed approach, while initially effective for individual tasks, created significant inefficiencies. Data was duplicated, inconsistent, and difficult to share across different operational areas. Imagine a sales team entering customer orders into one system, while the inventory department managed stock levels in another, and finance tracked receivables in a third.

The disconnect meant that updating customer information in one place didn’t automatically reflect in others, leading to errors, delays, and a lack of real-time visibility into the overall health of the business. This fragmentation was the prevailing norm, a testament to the limited understanding of how interconnected business processes truly were.The visionary shift that led to the development of integrated business management systems was driven by the realization that a unified approach to data and processes was not just desirable, but essential for competitive survival and growth.

The core idea was to move away from isolated applications and towards a single, comprehensive platform that could manage and connect all critical business functions. This concept of a “single source of truth” became the cornerstone, aiming to eliminate data redundancy and ensure consistency across the organization. The foundational principles of these early comprehensive platforms revolved around the concept of data flow and process standardization.

Data was to be entered once and then made available to all relevant modules and users. Processes, from order fulfillment to financial reporting, were to be standardized and automated where possible, ensuring that operations ran smoothly and predictably. The primary objectives behind this monumental undertaking were clear: to improve efficiency, reduce operational costs, enhance decision-making through better data accuracy and accessibility, and ultimately, to provide a holistic view of the business’s resources and performance.

Core Concepts of Early Integrated Systems

The initial design of these comprehensive platforms was heavily influenced by a few core concepts aimed at achieving operational synergy. At its heart was the principle of a unified data repository, a central database where all business information resided. This eliminated the need for manual data re-entry and significantly reduced the chances of errors stemming from inconsistent data across disparate systems.

Data flow was meticulously designed to ensure that information moved seamlessly between different modules. For instance, a sales order entered into the sales module would automatically trigger updates in inventory, production planning, and financial accounting modules. This interconnectedness was crucial for real-time visibility and operational responsiveness.Process standardization was another key tenet. Instead of departments operating with unique, often undocumented, workflows, these integrated systems imposed a structured and consistent approach to business operations.

This meant defining best practices for common business activities and embedding them within the software. The objective was to ensure that regardless of who performed a task or in which department, the process would be executed in the same, optimized way, leading to predictable outcomes and easier auditing.The primary objectives driving the development of these systems were multifaceted. A paramount goal was to achieve greater operational efficiency by automating routine tasks and streamlining workflows.

Reducing manual effort and eliminating redundant processes directly translated into cost savings. Furthermore, providing accurate, up-to-date information to management was a critical driver. This enabled better-informed decision-making, allowing leaders to identify trends, anticipate problems, and capitalize on opportunities with greater confidence. Ultimately, the aim was to gain a comprehensive understanding and control over the organization’s resources – from raw materials and labor to financial assets and customer relationships – enabling more strategic planning and execution.

Initial Challenges in Adopting Integrated Approaches

The transition to integrated business management systems was not without its hurdles. Businesses faced significant initial challenges in adopting these new, comprehensive approaches to operational oversight. One of the most prominent was the substantial financial investment required. Implementing such systems often involved considerable upfront costs for software licenses, hardware upgrades, and extensive customization to fit the specific needs of the organization.

Beyond the financial aspect, there was the challenge of change management and user adoption. Employees accustomed to their familiar, albeit fragmented, systems often resisted learning new processes and navigating a unified platform. This resistance could stem from a fear of the unknown, a perceived increase in workload during the transition, or a lack of understanding of the long-term benefits.

“The success of an integrated system hinges not just on the technology, but on the people who use it.”

Another significant challenge was the complexity of data migration. Transferring vast amounts of data from legacy systems into a new, unified database was a painstaking process. Ensuring data integrity, accuracy, and completeness during this migration was paramount to the success of the new system. Inaccurate or incomplete data would undermine the very purpose of integration, leading to flawed reporting and decision-making.

Furthermore, the integration itself was technically challenging. Ensuring that different modules communicated effectively and that the system could handle the volume and complexity of an organization’s operations required significant technical expertise and careful planning. Businesses also had to grapple with the potential disruption to ongoing operations during the implementation phase. A poorly managed rollout could lead to downtime, lost productivity, and customer dissatisfaction, making the transition a high-stakes endeavor.

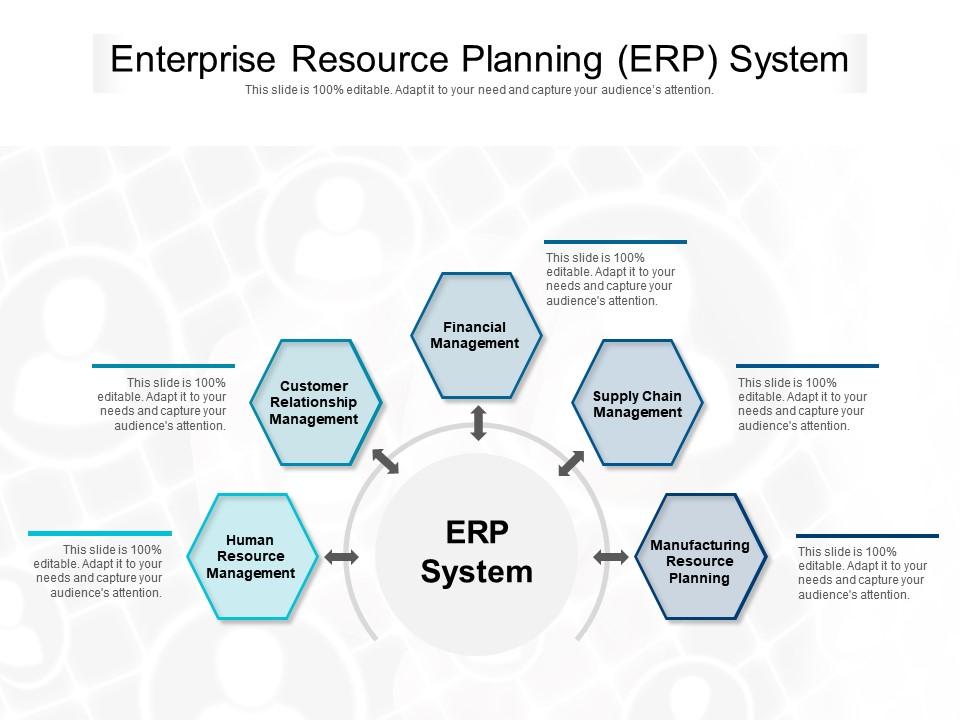

Unpacking the multifaceted modules that comprise a modern enterprise resource planning solution.

Modern ERP systems are not monolithic entities; rather, they are sophisticated collections of interconnected modules, each designed to manage a specific business function. This modular architecture allows organizations to select and implement the functionalities most relevant to their operations, while still benefiting from a unified data backbone. The true power of an ERP lies in how these individual components work in concert, transforming raw data into actionable intelligence and streamlining processes across the entire enterprise.Understanding the purpose and interplay of these modules is key to appreciating the transformative potential of ERP.

Each module acts as a specialized data hub, collecting, processing, and sharing information with other relevant parts of the system. This seamless flow of data eliminates silos, reduces manual data entry, and provides a holistic view of the business.

Core Functional Areas within ERP Systems

A robust ERP solution typically encompasses a wide array of functional areas, each addressing a critical aspect of business operations. These modules are the building blocks of an integrated system, designed to automate and optimize tasks from the shop floor to the executive suite. The specific modules implemented can vary based on industry and business needs, but certain core areas are almost universally present.Here are some of the most common and essential modules found in modern ERP systems:

- Finance and Accounting: This module is the financial heart of the ERP. It manages all aspects of financial transactions, including general ledger, accounts payable, accounts receivable, budgeting, fixed asset management, and financial reporting. It ensures compliance with accounting standards and provides real-time visibility into the company’s financial health.

- Human Resources Management (HRM): Covering the entire employee lifecycle, this module handles payroll processing, benefits administration, recruitment, onboarding, performance management, time and attendance tracking, and employee data management. It aims to optimize workforce productivity and ensure compliance with labor laws.

- Supply Chain Management (SCM): This encompasses a broad range of activities related to the flow of goods and services from origin to consumption. Key components include procurement, inventory management, warehouse management, logistics, demand planning, and order fulfillment. SCM modules are crucial for efficiency and cost reduction in operations.

- Customer Relationship Management (CRM): Focused on managing all aspects of a company’s interactions with its customers, this module handles sales force automation, marketing campaign management, customer service, and support. Its goal is to enhance customer satisfaction, retention, and drive sales growth.

- Manufacturing and Production Planning: For companies involved in production, this module is vital. It includes functionalities for material requirements planning (MRP), capacity planning, production scheduling, shop floor control, quality management, and bill of materials (BOM) management. It ensures efficient and cost-effective manufacturing processes.

Synergistic Operational Benefits of Module Integration

The true power of an ERP system is unlocked when its various modules are seamlessly integrated. This integration moves beyond simple data sharing; it creates a dynamic ecosystem where processes flow smoothly across departments, leading to significant operational efficiencies and strategic advantages. When modules like finance, human resources, supply chain, and customer relationship management work in unison, they eliminate redundant tasks, improve data accuracy, and enable better decision-making.For instance, an order placed through the CRM module can automatically trigger inventory checks in SCM, initiate production planning in the manufacturing module, and subsequently update financial records in the finance module.

This interconnectedness reduces lead times, minimizes errors, and provides a comprehensive view of customer orders from initial contact to final delivery and payment. The result is a more agile, responsive, and profitable business.

Typical Data Exchange and Impact on Business Intelligence

The exchange of data between ERP modules is fundamental to its operation and is the primary driver of enhanced business intelligence. Each transaction or event recorded in one module generates data that can inform and influence decisions in others. This constant flow of information, when properly analyzed, provides a 360-degree view of business performance.Typical data points exchanged include:

- Sales Orders (CRM) trigger inventory depletion and revenue recognition (Finance) and initiate fulfillment requests (SCM).

- Purchase Orders (SCM) update accounts payable (Finance) and can trigger raw material needs for production (Manufacturing).

- Employee Time Sheets (HRM) inform payroll processing (Finance) and can be allocated as direct labor costs to production orders (Manufacturing).

- Production Completion Reports (Manufacturing) update inventory levels (SCM) and contribute to cost of goods sold (Finance).

- Customer Payment Information (Finance) updates customer account status (CRM) and impacts cash flow forecasts (Finance).

This rich, interconnected data forms the foundation for powerful business intelligence. By analyzing trends, patterns, and anomalies across these integrated data sets, businesses can gain deep insights into customer behavior, operational bottlenecks, financial performance, and market dynamics. This allows for more accurate forecasting, proactive problem-solving, and strategic planning, ultimately leading to a significant competitive advantage.

The true value of ERP lies not just in automating individual tasks, but in weaving them together into a cohesive operational fabric, thereby transforming data into strategic insight.

Conceptual Module Interaction in a Hypothetical Manufacturing Company

To illustrate how these modules interact, consider a hypothetical manufacturing company, “InnovateTech Manufacturing,” that produces custom electronic components.Below is a conceptual representation of module interactions:

| Triggering Event/Module | Data Exchanged | Interacting Modules | Business Impact/Outcome |

|---|---|---|---|

| New Customer Order Received (CRM) | Customer details, product specifications, quantity, desired delivery date. | Finance, SCM, Manufacturing | Order entered, credit check performed, inventory availability confirmed, production schedule adjusted. |

| Raw Material Shortage Identified (SCM – Inventory) | Specific material name, quantity needed, reorder point. | Finance, Manufacturing | Automated purchase requisition generated, production planner notified of potential delay, financial impact assessed. |

| Production Completed (Manufacturing) | Finished goods quantity, batch number, quality inspection results, labor hours. | SCM, Finance | Inventory updated, cost of goods sold calculated, sales order fulfillment status updated. |

| Customer Invoice Generated (Finance) | Invoice number, customer account, items billed, payment terms, amount due. | CRM | Customer account updated with outstanding balance, follow-up reminders can be automated. |

Charting the strategic advantages and tangible benefits derived from implementing a unified business management platform.: Enterprise Resource Planning

Implementing an Enterprise Resource Planning (ERP) system is a significant undertaking, but the rewards it offers in terms of strategic advantage and tangible benefits are substantial. At its core, an ERP solution acts as the central nervous system for an organization, connecting disparate functions and providing a holistic view of operations. This unification is not merely about convenience; it’s about unlocking a new level of operational excellence, strategic agility, and ultimately, profitability.

The shift from fragmented systems to a single, integrated platform fundamentally alters how businesses operate, make decisions, and respond to market dynamics. The advantages span across every department, from finance and human resources to supply chain and customer service, creating a ripple effect of positive outcomes throughout the entire organization.A truly integrated business management platform moves beyond simply housing data; it transforms raw information into actionable intelligence.

This is achieved through the seamless flow of data across all modules, ensuring that every decision is informed by the most current and accurate picture of the business. The benefits are not abstract; they translate into concrete improvements in efficiency, cost reduction, and customer satisfaction. Organizations that embrace this integrated approach position themselves for sustainable growth and a competitive edge in today’s fast-paced business environment.

The strategic imperative to adopt such a system stems from the inherent inefficiencies and missed opportunities that plague companies reliant on siloed software.

Improved Decision-Making Through Real-Time Data Access and Enhanced Visibility

The bedrock of effective decision-making is accurate, timely information. A centralized ERP system demolishes data silos, consolidating information from every corner of the organization into a single, accessible database. This real-time data access means that managers and executives are no longer working with outdated reports or conflicting figures. Instead, they have an immediate, comprehensive view of critical business metrics, from inventory levels and sales pipelines to financial performance and production schedules.

This unparalleled visibility allows for proactive problem-solving and strategic planning, rather than reactive firefighting. For instance, a sales manager can instantly see if a product is in stock before promising a delivery date, preventing potential customer dissatisfaction. Similarly, the finance department can monitor cash flow in real-time, enabling quicker identification of potential shortfalls or opportunities for investment. This constant, unified pulse of the business empowers leaders to make informed choices with confidence, leading to better resource allocation, more accurate forecasting, and a significantly reduced risk of costly errors.

“In today’s dynamic business landscape, decisions made with yesterday’s data are already obsolete.”

The enhanced visibility provided by an ERP extends beyond simple reporting. Advanced analytics and business intelligence tools, often embedded within ERP solutions, can identify trends, predict outcomes, and highlight areas for improvement that might otherwise go unnoticed. This allows for a more strategic approach to management, where opportunities are seized and risks are mitigated before they escalate. The ability to drill down into specific data points, understand the underlying causes of performance fluctuations, and simulate different scenarios provides a level of strategic insight that is simply unattainable with disparate systems.

Operational Efficiencies Realized by Streamlining Workflows and Automating Repetitive Tasks

One of the most immediate and impactful benefits of an integrated ERP system is the dramatic improvement in operational efficiencies. By standardizing processes and automating manual, repetitive tasks, organizations can free up valuable employee time and reduce the likelihood of human error. Consider the procurement process: instead of manual purchase order creation, approvals, and invoice matching across different systems, an ERP can automate much of this.

A purchase requisition can be initiated, automatically routed for approval based on predefined rules, converted into a purchase order, and then matched against the received goods and vendor invoice, all within a single system. This drastically reduces processing times, minimizes errors, and ensures better control over spending.

“Automation is not about replacing people; it’s about empowering them to focus on higher-value activities.”

Another concrete example is in inventory management. Instead of manual stock counts and disparate spreadsheets, an ERP system tracks inventory in real-time as it moves through the supply chain – from receipt of raw materials to finished goods. This ensures accurate stock levels, reduces the risk of stockouts or overstocking, and optimizes warehouse operations. Production planning also benefits immensely. An ERP can integrate sales forecasts with production capacity and material availability, generating optimized production schedules that minimize downtime and maximize output.

Human resources processes, such as payroll, onboarding, and time tracking, can also be significantly streamlined and automated, reducing administrative burden and ensuring compliance. These are not minor tweaks; they represent fundamental shifts in how work gets done, leading to substantial gains in productivity and a more agile operational framework.

Cost-Saving Potentials of an Integrated System Versus Maintaining Disparate Software Solutions, Enterprise resource planning

The financial advantages of adopting an integrated ERP system are compelling when compared to the ongoing costs of maintaining multiple, disparate software solutions. While the initial investment in an ERP can seem significant, the long-term savings are often substantial. Maintaining separate software packages for accounting, CRM, inventory, HR, and other functions incurs multiple costs: licensing fees for each system, ongoing maintenance and support contracts, integration costs to make them “talk” to each other (which are often complex and imperfect), and the significant cost of IT staff or external consultants required to manage and troubleshoot these individual systems.Furthermore, the inefficiencies inherent in managing siloed systems lead to hidden costs.

These include duplicated data entry, errors stemming from manual data transfer, increased training time for employees who need to learn multiple interfaces, and delays in critical business processes due to system incompatibilities. An ERP, by consolidating these functions into a single platform, eliminates many of these redundant costs. Licensing fees are consolidated, IT support becomes more streamlined, and the need for complex, fragile integrations is drastically reduced.

“The true cost of fragmented technology is not just in the licenses, but in the lost productivity and missed opportunities.”

Consider the example of a company that uses a separate CRM, accounting software, and an inventory management system. Each system has its own maintenance cost, its own IT support needs, and its own set of potential integration issues. If a sale is made, data needs to be entered into the CRM, then potentially re-entered into the accounting system, and inventory levels updated separately.

An ERP handles all of this seamlessly. The cost savings are realized through reduced software expenditure, lower IT overhead, fewer errors leading to rework or lost revenue, and improved operational speed, which can translate into faster revenue cycles and better cash flow management. The total cost of ownership for an integrated ERP, when factoring in these efficiencies and cost reductions, often proves to be significantly lower than the cumulative costs of a patchwork of disparate systems.

Impact on Customer Satisfaction and Market Responsiveness

The ability to better manage resources and commitments through a unified business management platform has a direct and profound impact on customer satisfaction and market responsiveness. When an organization has a clear, real-time view of its inventory, production schedules, and order fulfillment status, it can make accurate promises to customers and reliably meet those commitments. This leads to fewer backorders, fewer delayed shipments, and a generally smoother, more positive customer experience.

For instance, a customer service representative using an ERP can instantly access a customer’s order history, current order status, and even projected delivery dates, allowing them to answer inquiries quickly and accurately, building trust and loyalty.Moreover, an integrated system enhances an organization’s ability to respond to market changes. If there’s a sudden surge in demand for a particular product, the ERP can quickly signal potential inventory shortages or production bottlenecks.

This allows for swift adjustments to production schedules, procurement of additional materials, or reallocation of resources to meet the increased demand. Similarly, if a competitor launches a new product or a new market trend emerges, an ERP can help an organization analyze its own capacity, inventory, and financial resources to formulate a rapid and effective response. This agility is crucial for maintaining a competitive edge.

“In a competitive market, the speed at which you can adapt and deliver is often the key differentiator.”

The improved communication and collaboration facilitated by an ERP also play a vital role. When sales, production, and logistics teams are all working with the same, up-to-date information, they can coordinate their efforts more effectively. This seamless coordination translates into faster order processing, more efficient delivery, and a reduced likelihood of miscommunication that can lead to customer frustration. Ultimately, an organization that can efficiently manage its resources, fulfill its commitments, and adapt quickly to market dynamics is an organization that can consistently delight its customers and outperform its competitors.

Navigating the intricate journey of selecting and deploying an enterprise resource planning system within a complex organizational structure.

Implementing an ERP system is a significant undertaking, especially for large and complex organizations. It’s a journey that requires meticulous planning, strategic decision-making, and a deep understanding of the organization’s unique needs and operational intricacies. The selection and deployment phases are critical junctures that can determine the success or failure of the entire initiative.This section delves into the essential steps and considerations involved in navigating this complex process, from identifying the right solution to ensuring its seamless integration and widespread adoption across the enterprise.

Critical Phases in the ERP Selection Process

The selection of an ERP system is not a casual decision; it involves a structured, multi-stage approach to ensure the chosen solution aligns perfectly with the organization’s current and future requirements. This process typically begins with a thorough understanding of what the business truly needs.The initial phase involves a comprehensive needs assessment. This means diving deep into existing business processes, identifying pain points, and defining clear objectives for the new ERP system.

This stage often includes workshops with various departments, stakeholder interviews, and a detailed analysis of current workflows. Following this, a request for proposal (RFP) is usually drafted, outlining these requirements for potential vendors. Vendor evaluation is a rigorous process where proposals are scrutinized, demonstrations are reviewed, and references are checked. Key factors here include the vendor’s industry experience, the system’s functionality, scalability, technology stack, and the total cost of ownership.

Finally, system configuration involves tailoring the chosen ERP solution to fit the specific business processes identified during the needs assessment, ensuring it can handle unique operational demands.

Step-by-Step Procedural Guide for Successful ERP Implementation

A well-defined implementation plan is the backbone of a successful ERP deployment. It’s about more than just installing software; it’s about transforming how the organization operates. This guide Artikels a structured approach to ensure a smooth transition and maximize user engagement.The process begins with a detailed project plan, outlining scope, timelines, resources, and responsibilities. This is followed by system setup and configuration, where the ERP is tailored to meet the specific business requirements.

Data migration is a crucial, often complex, step that involves transferring existing data into the new system. Thorough testing, including unit testing, integration testing, and user acceptance testing (UAT), is paramount to identify and resolve any issues before go-live. Training is a continuous effort, starting with key users and cascading to all end-users. Change management strategies are woven throughout the entire process, focusing on communication, stakeholder engagement, and addressing user concerns to foster buy-in and minimize resistance.

Post-implementation support and optimization are ongoing, ensuring the system continues to deliver value and adapt to evolving business needs.

Importance of Data Migration and Potential Pitfalls

Data migration is arguably one of the most challenging yet critical aspects of an ERP implementation. The accuracy and integrity of data in the new system directly impact its usability and the value it delivers. A well-executed data migration ensures a seamless transition, while a poorly managed one can lead to significant operational disruptions and a loss of confidence in the new system.The process involves extracting data from legacy systems, cleansing it to remove inaccuracies and duplicates, transforming it into a format compatible with the new ERP, and finally loading it into the target system.

Potential pitfalls include incomplete data extraction, data corruption during transformation, incorrect data mapping, and insufficient validation. Overlooking data cleansing can lead to the migration of “dirty” data, which can cripple reporting and decision-making in the new system. Insufficient testing of the migration process itself is another common mistake. Organizations must allocate sufficient time and resources to this phase, treating it with the same importance as system configuration and testing.

Key Considerations for ERP Deployment Project Teams

Successfully overseeing the deployment of a transformative technology like an ERP system requires a project team equipped with the right skills, a clear vision, and robust strategies. The following considerations are vital for project teams to navigate the complexities and ensure a positive outcome.

- Executive Sponsorship and Stakeholder Alignment: Strong, visible support from senior leadership is crucial for driving the project forward, resolving conflicts, and ensuring organizational buy-in. Regular communication and engagement with all key stakeholders, from departmental heads to end-users, are essential to manage expectations and foster a sense of ownership.

- Clear Scope Definition and Management: A well-defined project scope, with clear objectives and deliverables, is fundamental. The team must implement strict change control processes to manage scope creep, ensuring that any additions or modifications are thoroughly evaluated for their impact on timelines, budget, and resources.

- Robust Project Management and Communication: Establishing a comprehensive project management framework, including detailed timelines, resource allocation, risk management, and quality assurance plans, is non-negotiable. Open, transparent, and frequent communication channels must be maintained across all project levels and with the wider organization to keep everyone informed and engaged.

- Comprehensive Training and Change Management: Developing and executing a thorough training program tailored to different user roles is critical for user adoption. This should be complemented by a proactive change management strategy that addresses user concerns, highlights the benefits of the new system, and provides ongoing support to facilitate a smooth transition.

- Thorough Testing and Data Validation: Implementing a rigorous testing strategy that covers all aspects of the ERP system, from individual modules to end-to-end processes, is paramount. This includes extensive user acceptance testing (UAT) to ensure the system meets business requirements. Equally important is the meticulous validation of migrated data to guarantee its accuracy and integrity in the new environment.

Exploring the dynamic interplay between enterprise resource planning systems and emerging technological advancements.

Enterprise Resource Planning (ERP) systems, once viewed as monolithic on-premise solutions, are now undergoing a profound transformation driven by a wave of emerging technologies. This evolution is not merely about adding new features; it’s about fundamentally reshaping how businesses operate, manage data, and achieve strategic objectives. The integration of these advancements is creating more agile, intelligent, and accessible business management platforms than ever before.The convergence of ERP with cutting-edge technologies is unlocking unprecedented levels of efficiency, insight, and operational flexibility.

From the foundational shift brought about by cloud computing to the predictive power of AI and the real-time data streams from IoT, these advancements are creating a more connected and responsive business ecosystem. Mobile technology further democratizes access, ensuring that critical business functions are at the fingertips of decision-makers and employees, regardless of their location. This synergy is propelling businesses towards a future of proactive management and continuous innovation.

Cloud Computing’s Revolution in ERP Accessibility and Scalability

Cloud computing has been a game-changer for Enterprise Resource Planning systems, fundamentally altering their accessibility and scalability. Historically, ERP implementations were costly, time-consuming, and required significant on-premise infrastructure, including servers, data centers, and IT personnel for maintenance. This created a barrier to entry, particularly for small and medium-sized businesses. The advent of cloud-based ERP solutions, often delivered as Software-as-a-Service (SaaS), has democratized access to these powerful tools.

Businesses can now subscribe to ERP functionalities, eliminating the need for substantial upfront capital investment in hardware and software licenses. This pay-as-you-go model makes advanced business management accessible to a wider range of organizations.Furthermore, cloud ERP offers unparalleled scalability. As a business grows, its needs for processing power, storage, and user licenses can fluctuate. Cloud infrastructure allows for dynamic scaling; resources can be provisioned or de-provisioned almost instantly in response to demand.

This means a company can expand its operations, add new modules, or accommodate a surge in users without the lengthy procurement and installation cycles associated with on-premise systems. Conversely, during leaner periods, resources can be scaled back, optimizing costs. This elasticity ensures that the ERP system remains a flexible asset, adapting to the evolving demands of the business rather than becoming a rigid constraint.

The continuous updates and maintenance managed by the cloud provider also mean businesses always have access to the latest versions and security patches without the burden of internal IT management.

Artificial Intelligence and Machine Learning for Predictive Analytics and Process Optimization

Artificial intelligence (AI) and machine learning (ML) are infusing ERP systems with an unprecedented level of intelligence, transforming them from reactive record-keeping tools into proactive decision-making engines. These technologies enable sophisticated predictive analytics, allowing businesses to forecast future trends, identify potential risks, and anticipate customer needs with remarkable accuracy. For instance, ML algorithms can analyze historical sales data, market trends, and even external factors like weather patterns to predict demand for specific products.

This allows for more efficient inventory management, reducing overstocking and stockouts, and optimizing production schedules.Beyond prediction, AI and ML are instrumental in process optimization. They can identify bottlenecks in workflows, suggest improvements, and even automate routine tasks. In areas like supply chain management, AI can optimize logistics routes, predict delivery times, and proactively alert stakeholders to potential disruptions. In finance, ML can detect fraudulent transactions with higher accuracy than traditional methods and automate invoice processing.

The ability of these systems to learn from data over time means that their predictive and optimization capabilities continuously improve, leading to ongoing enhancements in operational efficiency and strategic agility. For example, a manufacturing company might use ML to analyze sensor data from its machinery, predicting potential equipment failures before they occur, thereby minimizing downtime and costly repairs.

The Internet of Things (IoT) for Real-Time Operational Data Integration

The Internet of Things (IoT) plays a crucial role in bridging the gap between the physical operational world and the digital realm of ERP systems by providing a continuous stream of real-time data. Sensors embedded in machinery, vehicles, inventory, and even products can collect a vast array of information, such as temperature, location, performance metrics, and usage patterns. This data, when fed directly into the ERP framework, offers an unparalleled level of visibility into day-to-day operations.

For example, in a manufacturing environment, IoT sensors on production lines can report machine status, output rates, and quality control measurements in real-time. This allows ERP systems to monitor production progress against schedules, identify deviations immediately, and trigger alerts for necessary interventions.This real-time data integration empowers businesses to move from a reactive to a proactive operational model. Instead of relying on periodic manual data entry or batch processing, ERP systems can now react instantaneously to changing conditions.

In logistics, GPS trackers on delivery vehicles can provide live updates on shipment locations and estimated arrival times, which are automatically reflected in the ERP’s order fulfillment modules. This not only enhances customer service through accurate tracking but also enables dynamic rerouting in case of unforeseen delays. The ability to capture and process this granular, real-time operational data allows for more accurate forecasting, better resource allocation, and improved overall efficiency across the entire value chain.

Mobile Technology’s Extension of ERP Reach and Usability

Mobile technology has dramatically expanded the reach and usability of Enterprise Resource Planning systems, transforming them from desktop-bound applications into accessible tools for a mobile workforce. The proliferation of smartphones and tablets has enabled employees to access critical ERP functionalities and data from virtually anywhere, at any time. This is particularly impactful for field service technicians, sales representatives, warehouse staff, and managers who are often away from their desks.

For instance, a sales representative can access customer order history, product availability, and pricing information directly from their mobile device while meeting with a client, enabling them to close deals more efficiently and provide instant, accurate quotes.Furthermore, mobile ERP applications often feature intuitive user interfaces designed for touch-screen devices, simplifying complex tasks and reducing the learning curve. This enhanced usability means that a broader range of employees can interact with the ERP system, contributing to better data accuracy and more timely information flow.

Warehouse workers can use mobile scanners to update inventory levels in real-time as goods are received or shipped, eliminating manual data entry errors and providing immediate visibility into stock. Managers can review reports, approve requisitions, and monitor key performance indicators (KPIs) on the go, facilitating quicker decision-making and greater responsiveness to business needs. This ubiquitous access fosters a more connected and agile business environment, where information is not a bottleneck but an enabler of productivity.

Identifying the potential obstacles and mitigation strategies encountered during the operationalization of enterprise resource planning.

Successfully implementing an ERP system is a significant achievement, but the journey doesn’t end with go-live. The true value of an ERP is realized through its effective operationalization, which involves overcoming various challenges to ensure full system utilization and achieve the anticipated return on investment. This phase requires a proactive approach to identify potential roadblocks and implement robust mitigation strategies.The operationalization phase is critical for ensuring that the ERP system becomes an integral part of the organization’s daily operations, driving efficiency and informed decision-making.

Without careful attention to this stage, even the best-designed ERP can fall short of its potential, leading to user frustration and unrealized benefits.

Achieving Full System Utilization and Realizing Expected Return on Investment

Organizations often encounter hurdles in getting users to fully embrace and leverage the ERP system, which directly impacts the realization of their expected return on investment (ROI). This can stem from a variety of factors, including resistance to change, a lack of perceived value, or insufficient understanding of the system’s capabilities.Common challenges include:

- Inadequate User Adoption: Employees may revert to old methods or find workarounds if the ERP is perceived as cumbersome or difficult to use, leading to incomplete data capture and process inefficiencies.

- Data Silos Persisting: If integration with other systems is not seamless or if users continue to maintain separate spreadsheets, the core benefit of a unified data view is lost.

- Unmet Business Process Alignment: A mismatch between ERP functionalities and actual business workflows can lead to frustration and a feeling that the system is hindering rather than helping.

- Underestimated Change Management Efforts: Failing to adequately prepare the organization for the shift in processes and responsibilities can result in resistance and a slow adoption rate.

To mitigate these challenges and ensure full system utilization, organizations must prioritize change management, ongoing communication, and a clear demonstration of the system’s benefits. Regular feedback loops with users can help identify pain points early on and allow for timely adjustments.

The Critical Need for Ongoing Training and Support

The initial training provided during implementation is just the first step in ensuring users can effectively leverage the ERP system’s capabilities over time. As business needs evolve and the system itself is updated, continuous training and readily available support are paramount.Effective ongoing training and support serve multiple crucial purposes:

- Empowering Users: Keeping users updated on new features and best practices ensures they can maximize their productivity and extract the most value from the system.

- Minimizing Errors: Well-trained users are less likely to make mistakes, which can have significant downstream impacts on data accuracy and operational efficiency.

- Facilitating Adaptation: As new employees join or roles change, a robust training program ensures a smooth transition and continued system proficiency.

- Enhancing System Mastery: Advanced training can help power users discover and implement more sophisticated functionalities, driving further process improvements.

Support channels should be easily accessible and responsive, offering a range of options from self-service knowledge bases and FAQs to direct assistance from IT or dedicated support teams. A proactive approach to support, anticipating common issues and providing preemptive guidance, can significantly enhance user satisfaction and system effectiveness.

A Framework for Continuous Improvement

The dynamic nature of business demands that ERP systems remain agile and adaptable. A framework for continuous improvement ensures that the ERP setup evolves in tandem with changing business needs, market dynamics, and technological advancements, preventing it from becoming a static, outdated solution.This framework typically involves several key components:

- Performance Monitoring and Analysis: Regularly tracking key performance indicators (KPIs) related to ERP usage and business outcomes helps identify areas for optimization. This includes analyzing system usage data, transaction volumes, and reporting accuracy.

- User Feedback Mechanisms: Establishing formal channels for users to provide suggestions, report issues, and highlight areas for enhancement is vital. This can include regular user group meetings, suggestion boxes, or dedicated feedback portals.

- Regular System Reviews: Periodic assessments of the ERP system’s configuration, modules, and integrations should be conducted to ensure they still align with current business objectives and best practices.

- Agile Development and Updates: Adopting an agile approach to implementing system updates, customizations, and new functionalities allows for quicker responses to evolving requirements and reduces the risk of large, disruptive changes.

- Benchmarking and Best Practices: Staying informed about industry trends and ERP best practices allows organizations to identify opportunities for improvement and competitive advantage.

By embedding these practices into the organizational culture, businesses can ensure their ERP remains a strategic asset, continuously contributing to their growth and efficiency.

Importance of Robust Security Protocols and Data Governance

In an integrated ERP environment, where vast amounts of sensitive business data are consolidated, robust security protocols and stringent data governance practices are not merely optional; they are fundamental necessities. Protecting this central repository of information is paramount to maintaining operational integrity, regulatory compliance, and stakeholder trust.The interplay between security and data governance is critical, with each reinforcing the other to create a secure and reliable data ecosystem.The following table Artikels key responsive columns for addressing security and data governance:

| Security Protocol/Governance Practice | Description and Importance | Potential Risks of Non-Compliance | Mitigation Strategies |

|---|---|---|---|

| Access Control and Role-Based Permissions | Ensuring that only authorized personnel have access to specific data and functionalities based on their roles and responsibilities. This is crucial for preventing unauthorized data modification or exposure. | Unauthorized data access, data breaches, internal fraud, compliance violations. | Implement strict role definitions, conduct regular access reviews, enforce multi-factor authentication, and utilize least privilege principles. |

| Data Encryption (In-Transit and At-Rest) | Protecting data from unauthorized viewing by scrambling it, both when it’s being transmitted across networks and when it’s stored on servers or databases. This safeguards data even if physical or network security is compromised. | Data interception, unauthorized data recovery from stolen devices or compromised storage, sensitive information exposure. | Utilize industry-standard encryption algorithms (e.g., TLS/SSL for transit, AES for rest), manage encryption keys securely, and ensure consistent application across all data storage points. |

| Regular Data Backups and Disaster Recovery | Establishing comprehensive procedures for regularly backing up all critical data and having a well-defined plan to restore operations in the event of system failures, cyberattacks, or natural disasters. This ensures business continuity and data availability. | Irreversible data loss, prolonged system downtime, significant financial losses, reputational damage, inability to meet legal or contractual obligations. | Implement automated, frequent backups to secure offsite locations, regularly test the disaster recovery plan, and define Recovery Time Objectives (RTOs) and Recovery Point Objectives (RPOs). |

| Data Quality Management and Integrity Checks | Implementing processes and tools to ensure the accuracy, completeness, consistency, and validity of data within the ERP system. This involves defining data standards and performing regular audits. | Flawed decision-making based on inaccurate data, operational inefficiencies, compliance issues, loss of trust in system outputs. | Establish clear data entry standards, implement data validation rules, conduct regular data cleansing exercises, and assign data ownership responsibilities. |

Concluding Remarks

In summation, enterprise resource planning represents a pivotal evolution in how businesses manage their operations, moving from fragmented systems to unified, intelligent platforms. The journey from initial concepts to modern, cloud-based solutions, enhanced by AI and IoT, underscores its adaptability and enduring value. By understanding its modules, strategic benefits, implementation challenges, and future trends, organizations can effectively harness ERP to drive efficiency, foster innovation, and achieve sustainable growth in an increasingly complex global market.

Essential FAQs

What is the primary goal of an ERP system?

The primary goal of an ERP system is to integrate all core business processes into a single, unified system to improve efficiency, provide better visibility, and support informed decision-making across the entire organization.

How long does it typically take to implement an ERP system?

Implementation timelines can vary significantly, ranging from a few months for smaller, simpler systems to over a year or even longer for large, complex, and highly customized ERP deployments.

What are the biggest challenges in ERP implementation?

Common challenges include resistance to change from employees, inadequate data migration, poor project management, insufficient user training, and scope creep. Technical challenges can also arise with system integration and customization.

Can small businesses benefit from ERP systems?

Yes, many ERP solutions are designed specifically for small and medium-sized businesses (SMBs), offering scalable modules and features that can help them compete by improving efficiency and managing growth effectively.

What is the difference between ERP and CRM?

While often integrated, ERP focuses on back-office operations like finance, HR, and supply chain, whereas CRM (Customer Relationship Management) focuses on front-office activities related to sales, marketing, and customer service.